HDPE -rørmaskine

QINGDAO COMRISE MACHINERY CO., LTD.

Our main product is HDPE Pipe Machine

The main products are popular in the domestic market, such as the East China market, Southwest market, Northeast market, Central China market, etc. The products are also exported to international markets, including Russia, Australia, Southeast Asia, the Middle East, and Eastern Europe. Africa and other country.

Pe pipe

Good hygiene performance: During the processing of PE pipes, no heavy metal salt stabilizers are added, the material is non-toxic, there is no scaling layer, and there is no bacterial growth, which solves the hidden danger of secondary pollution of urban drinking water.

Excellent corrosion resistance: except for a few strong oxidants, it can withstand corrosion from various chemical media; No electrochemical corrosion.

Long service life: PE pipes can be safely used for more than 50 years at rated temperature and pressure.

Better impact resistance: PE pipes have good toughness, high impact resistance, and can withstand heavy objects directly passing through the pipeline will not cause the pipeline to rupture.

Similer Product

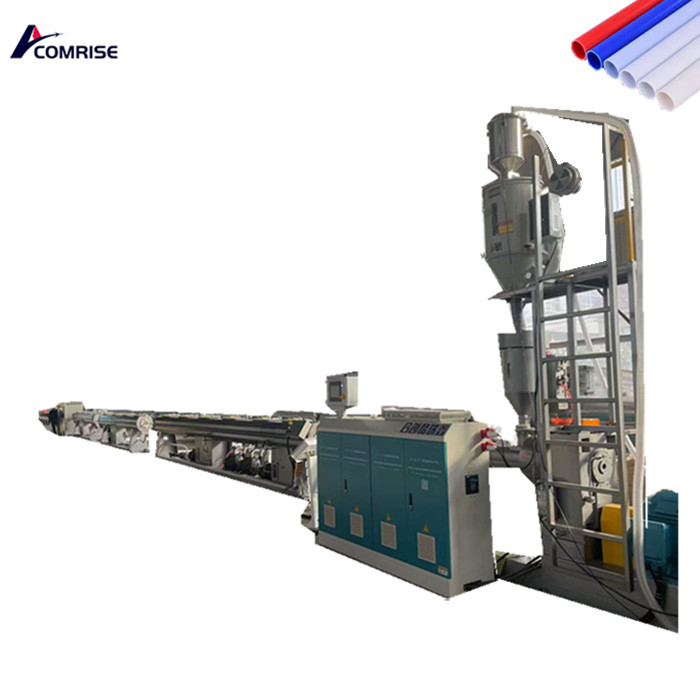

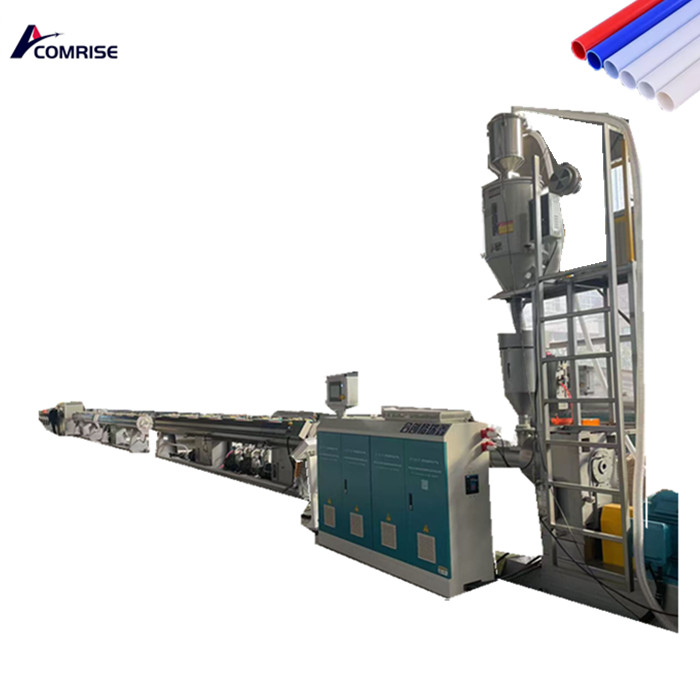

The PE (Polyethylene) pipe machine is a specialized piece of equipment designed for the production of polyethylene pipes. These pipes are widely used in various applications, including water supply, gas distribution, irrigation, and drainage systems. The PE pipe machine consists of several key components that work together to ensure efficient and high-quality pipe production.

ApplicationsWater Supply Systems: Municipal water distribution networks, residential and commercial water supply lines.

Gas Distribution: Natural gas pipelines, propane distribution systems.

Irrigation Systems: Agricultural irrigation, landscaping, and golf course watering systems.

Drainage Systems: Stormwater management, sewage systems, and industrial drainage.

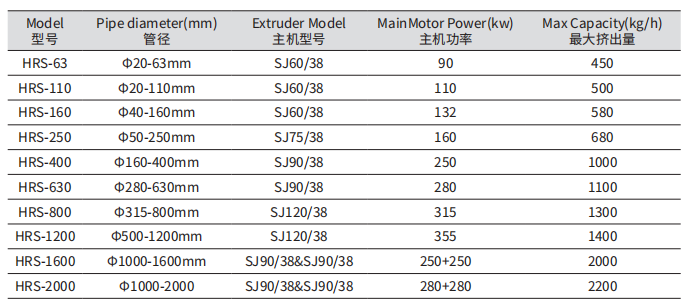

Specifiation Parameters

(1)ExtruderFunction:

The extruder is responsible for melting and extruding the polyethylene pellets into a continuous tube.

Features: High torque drive system, precision temperature control, and efficient screw design for optimal material

processing.

Longth ratio L / D :33:1

Material quality: 38CrMoAlA

Siemens motor

ABB inverter

Siemens PLC computer control panel

(2)New technology die head

The extrusion die adopts spriral structure to ensure uniform melt temperature, completely eliminate weld lines, overcome the stripe defect caused by blue die, and produce pipe products with smooth inner and outer walls and good compactness.

Pressure grades: as to customer table

(3)Vacuum sizing water tankFunction:

The cooling system rapidly cools the extruded pipe to maintain its shape and structural integrity.

Features: Multi-stage cooling tanks with adjustable water flow rates and temperature control to ensure consistent cooling.

vacuum pump:3 + 4 KW, 2 sets

Water pump: 3 + 4 KW, 2 sets

Tank material: 100% Stainless steel

Length: 6000 mm

(4)Spray water tank

Water pump : 4 KW * 1 set

Water tank material:stainless steel

Length : 6000mm

Over all size :6500×500×1300mm

(5)Halling off machine:

The traction device is designed to be able to pull the pipe in a continuous and stable state. Its compact structure, maintenance-free structure and absolute balance of operation are its outstanding features.

Clamping way:claw pneumatic

Traction speed:1-15m/min

Pulling motor:motor 1.5KW x 2

Mode of speed regulation:Frequency Control

(6)Cutting machine:

Cutting method:Rotary cutting with circular blade

Clamping way:Pneumatic clamp

Worktable movement way: Synchronous follow up, pneumatic reset

Revolution motor power:1.5KW

Method of electric control : Independent setting of high-speed counter and PLC linkage

(7)Double station winding machine

The winding machine is used for small-sized 20-63mm PP PE PPR HDPE LDPE pipes. High winding efficiency

(8)Auto stocker

Stacker used for big size pipe.

About Us

High Production Efficiency:

Advanced extrusion technology ensures high output and consistent quality.

Automated control systems for precise operation and reduced labor costs.

Versatile Material Handling:

Capable of processing a wide range of polyethylene grades, including HDPE, MDPE, and LDPE.

Flexible production settings to accommodate different pipe diameters and wall thicknesses.

User-Friendly Interface:

Intuitive control panel with touch screen display for easy operation and monitoring.

Real-time data tracking and production statistics for better process control.

Robust Construction:

Heavy-duty frame and components for durability and long service life.

Low maintenance requirements and easy access for routine servicing.

Environmental Compliance:

Energy-efficient design to reduce power consumption and operating costs.

Minimal waste generation and recycling options for sustainable production.

GET A QUOTATION NOW

- View as

Rørmaskine

Kamrisemaskineri er en førende kinesisk producent, der er specialiseret i ekstruderingsudstyr til plastikrørmaskine og produktionslinjer for rørmaskine, med omfattende brancheerfaring og teknisk ekspertise. Kamrise er forpligtet til at give globale kunder med høj kvalitet, højtydende løsninger til plastikrørproduktion, der serverer en lang række applikationer.

Læs mereSend forespørgselHDPE -rørmaskine

Kamrisemaskiner med høj densitet polyethylen HDPE-rørmaskiner er specialudstyr, der bruges til at fremstille HDPE-rør, som er vidt anvendt i forskellige brancher på grund af deres holdbarhed, fleksibilitet og modstand mod korrosion og kemikalier. Disse HDPE -rørmaskiner af høj kvalitet er designet til at ekstrudere HDPE -materiale i rør med forskellige diametre og tykkelser, der serverer applikationer såsom vandforsyning, gasfordeling, kloaksystemer og industrielle rørledninger.

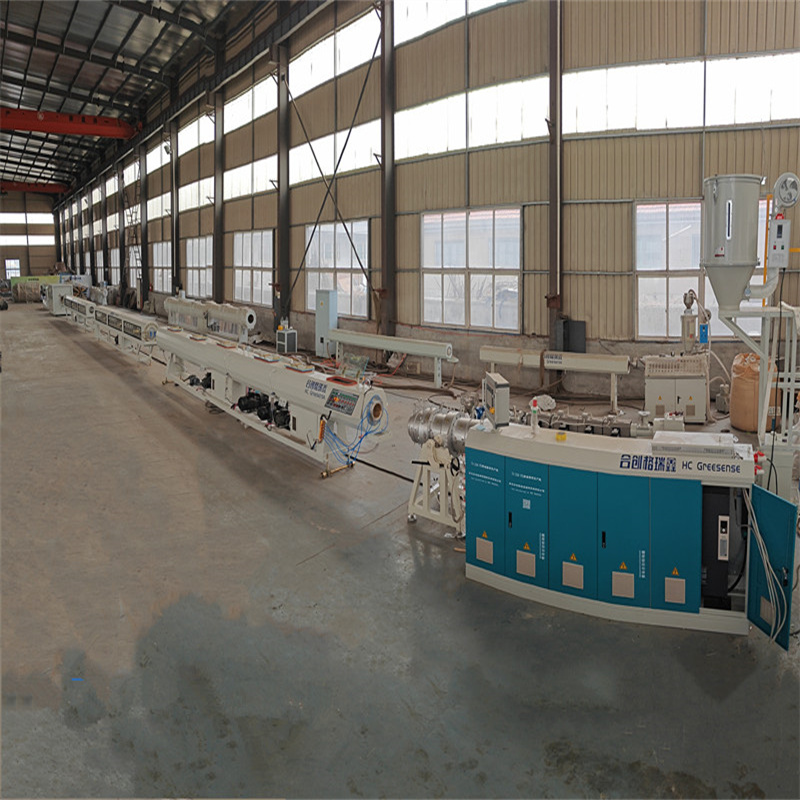

Læs mereSend forespørgselHDPE Pipe Making Machine

HDPE -rørfremstillingsmaskine og PP -gasvandforsyningsrørproduktionslinje produceret af kammeratsmaskiner bruges hovedsageligt til produktion af landbrugsvandforsyning og -drenering, bygning af vandforsyning og dræning, kabelsnedlægning og andre aspekter. HDPE-rørfremstillingsmaskine består af et vakuumkvalitativt bord, en trækkraftmaskine, en skæremaskine, et flippestativ osv. Den enkelte skrue-ekstruder- og trækkraftmaskine vedtager importerede reguleringsenheder med variabel frekvenshastighed og vakuumpumpe- og trækkraftmotoren er alle produkter med høj kvalitet. Traktionsmaskinen er udstyret med to klo, tre klo, fire klo, seks klo, otte klo, ti klo, tolv klo og andre trækkraftmetoder. Du kan vælge chipfrit skæring, savbladskæring eller planetarisk skæring, og enheden har pålidelig ydelse og høj produktionseffektivitet. Vores firma kan fremstille HDPE -rørmaskine, indre væg spiralrør, indre væghulrør og kerneskumrør med dedikeret udstyr i henhold til brugerkrav. Efter udskiftning af ekstruderen kan vi fremstille PP, PE, ABS, PPR, PEX, siliciumkerør og andre materialrør. Den planetariske skæremaskine vedtager fuldautomatisk computer numerisk kontrol, som har fordelene ved let drift og pålidelig ydeevne

Læs mereSend forespørgselProduktionslinje af høj kvalitet HDPE Pipe

QINGDAO COMRISE MACHINERY main production line including high-efficiencyHigh quality HDPE pipe production line, PE large-diameter hollow-wall winding pipe production line, PPR cold and hot water supply pipe production line, the inner-rib winding sewage pipe production line, the double-plastic composite winding pipe production line, the continuous winding carat pipe production line, and the PE large-diameter hollow wall production line, the plastic coated corrugated pipe production line,PE black jacket Isoleringsrørproduktionslinje og PE -ark/brætproduktionslinje. HC har mere end 20 slags nye produkter, der sælges verden bredt som Rusland, Sydøstasien, Mellemøsten og Afrika.

Læs mereSend forespørgselHøj konfiguration og højhastigheds 20-110mm HDPE-rørmaskine

PE (polyethylen) rørmaskine er et specialiseret udstyr designet til produktion af polyethylenrør. Disse rør er vidt brugt i forskellige applikationer, herunder vandforsyning, gasfordeling, kunstvanding og dræningssystemer. Høj konfiguration og højhastigheds 20-110mm HDPE-rørmaskine består af flere nøglekomponenter, der arbejder sammen for at sikre effektiv og høj kvalitet rørproduktion

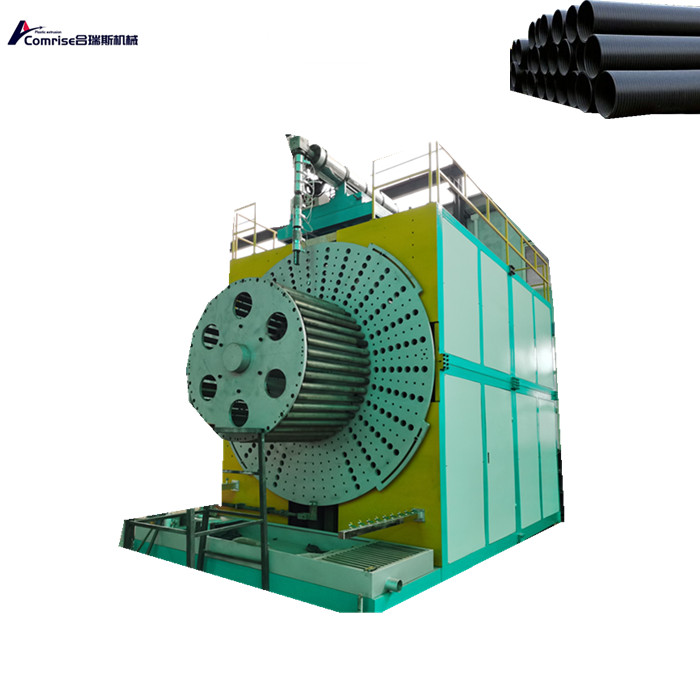

Læs mereSend forespørgselNy hule væg spiralviklingsrørmaskine

Ny hule væg spiralviklingsrørmaskine er blevet brugt med succes som dræningsrør til at erstatte cementrør og støbejernsrør og har brede markedsudsigter. Vores firma er en autoritativ producent af hule viklingsrør i stor diameter i Kina med stærke tekniske fordele og rig erfaring med implementering af produktion og installation. Udstyrets design er avanceret, konfigurationen er high-end, operationen er pålidelig, levetiden er lang, og output fra den samme model er langt højere end industrieniveau. Især til modeller med ultra stor diameter har vi rig erfaring og kan imødekomme behovene hos store avancerede kunder i indlandet og i udlandet. Resultatindikatorerne for produktionslinjen har nået det internationale førende niveau.

Læs mereSend forespørgsel